Toyota: Suicide and Worker Depression at the World’s Most Profitable Manufacturer

by Kamata Satoshi

Toyota is the most profitable company in Japan. Its net profit for fiscal 2004 was reported at 1.16 trillion yen ($10.5 billion). This is after-tax, clear profit, the first time in the history of Japanese capitalism that a company has passed one trillion yen in profits.

Toyota sold 1.3 million fewer cars than world-leader General Motors and had some $22.7 billion less in gross sales, yet its profit was twice that of GM’s. What this tells you is how thoroughly Toyota has implemented cost-reduction measures.

Toyota ranks fourth in the world in profit (#1 is ExxonMobil), but setting aside the oil companies and banks, Toyota is number one among manufacturers. “Wring even a dry rag” is Toyota’s motto when it comes to the pursuit of profit, and I have often written about the pains of its “wrung-out” subcontractors and the suffering of its workers.

Close to 10,000 Term Laborers Employed

Toyota headquarters is at Number 1, Toyota-cho (town), Toyota-shi (city), about fifty minutes by train from Nagoya in central Japan. The city was once called Koromo, a beautiful name that evokes priestly robes, but the Toyoda family that founded the company had it changed to the very commonplace Toyota. This is the only place in Japan where a city took on the name of a family, and where a town took on the name of a company.

Standing in front of Toyota headquarters in the morning, a crowd of white-shirted men pass before one’s eyes. They are likely technicians, on their way to work in the technical center across the street, and since they don’t interact with the public, they have no need to wear suits. This in itself conveys the self-confidence of a world corporation located in the countryside.

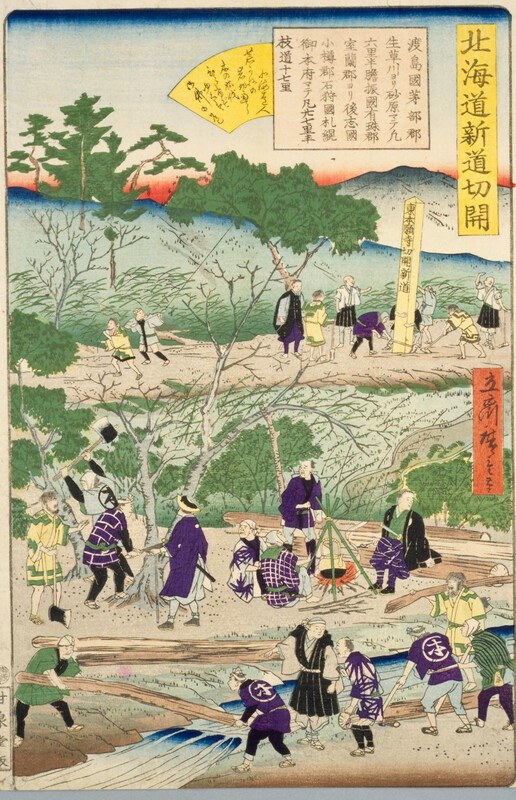

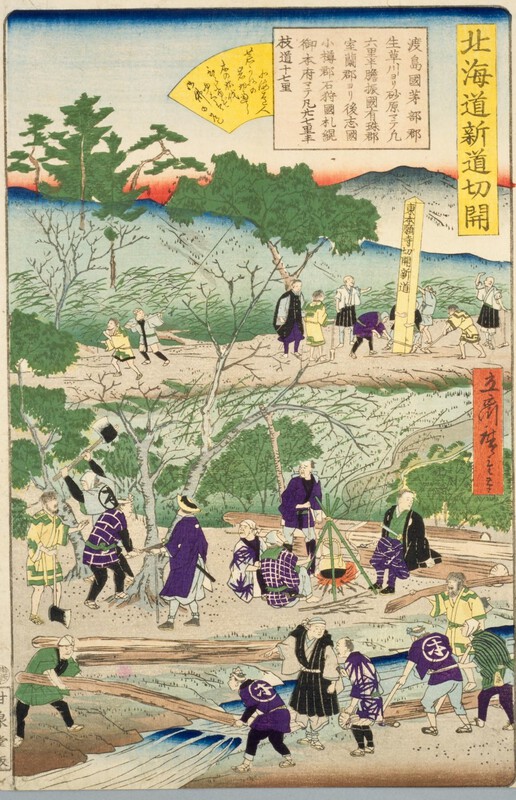

Kitty-corner from headquarters is the Headquarters Plant, where truck chassis and other parts are produced. I watched as a long-bodied carrier car entered through the gate. Thirty-one years ago, I dragged my tired legs through that gate every day for six months. I worked as what they call a “term laborer,” assembling transmissions, and wrote about it in a book called Jidosha zetsubo kojo–Aru kisetsuko no nikki (Auto Factory of Despair: The Diary of a Seasonal Worker).

Just glimpsing the layout of the plant from the street brought back memories of my exhaustion during those days. Nonetheless, I also felt a certain nostalgia for the place, and I wanted to take a look around inside, but where there once had been free access from the public road, a large gatehouse like a freeway toll booth has been erected and public access is restricted.

Back then my total wages, including overtime and night shift allowance, amounted to 79,000 yen ($720 at today’s exchange rate) a month. Today, the large newspaper ads Toyota runs for “term employees” promise a monthly wage of 254,430 yen ($2300), a threefold increase in thirty-one years.

Toyota’s 1972 results were reported in the Chunichi shimbun, the regional newspaper, under the headline, “First Corporation in the Country to Reach 32 Billion Yen in Profits, Assures Top Earnings Spot for the Second Year Running.” Aside from the period of the 1970’s oil shock, Toyota has retained the “top earnings spot” throughout the last three decades. Its current 1.16 trillion yen in profits represents more than a thirty-fold increase from the time when I worked there.

I’ll give just one other number. Back then, Toyota had a total of 41,000 employees, a number that has only grown about fifty percent to 65,000. And it still has managed to increase profits by thirty times. At Toyota, it is not enough to talk about “labor-savings”; its more a matter of bald-faced “people-savings.” During this period, what has increased dramatically is the number of my fellow “term employees.” Where their number then stood at about 3,000, now, “We employ about ten thousand” (according to chairman Okuda Hiroshi). This statement was made in May, in response to queries from the press corps as to whether Toyota would take on some of the excess employees from ailing Mitsubishi Motors, but the expression “employ” is somewhat misleading. Low-cost term employees exist not to be employed, but rather to be discarded.

One would think that chairman Okuda, who is also chairman of Nippon Keidanren (the Japan Business Federation), might feel some embarrassment at utilizing term employees, the epitome of insecure employment, to the fullest extent, while reaping the highest profits in the world. Even more so, given that seventy percent of these profits are generated in North America and elsewhere overseas, as this world corporation boasts.

From the City of Sorrow to the City of Secrets

I met up with some old friends who work for Toyota. They told me that, with the rapid expansion of Toyota’s overseas operations, many workers were being sent overseas as training leaders. This has resulted in shortages of workers in the plants, and that, in hiring term employees, preferential treatment was given to workers who have experience on auto assembly lines and thus can be put to work immediately. Four months is the minimum term of employment, but the maximum is two years, eleven months. In place of the “seasonal worker” that had been a synonym for migrant labor, it is now long-term temporary workers who are pounding out super-profits on the factory floor.

As elsewhere in Japan, office workers in their fifties are now treated as redundant labor. For jobs such as computer repair, outside contractors who are paid less than half the wages of regular employees are being introduced in large numbers. On the plant floor, there is strong dissatisfaction with a new wage system introduced in April. The new arrangement replaces age-based pay with a system of skill-based pay, with peak rates paid to workers in their thirties and forties, and wage reductions after the age of fifty-one. “It’s worse than a wage freeze. It amounts to a rollback of wages,” workers reported, but not without contradictory feelings. “At the same time, we’re still paid more than people at other companies. But even so, why is it that only the company makes money?”

If one complains to the leaders of the union local, the threatening response is, “Find me a company that will hire you for the wages you’re being paid now.” This is one of the fruits of “labor-management harmony,” with an assist from the financial instability of nearby Mitsubishi Motors, and the workers of the world’s number one corporation simply wither away.

Toyota has always suffused the workplace with a crisis consciousness in order to suppress wages. While I was working there, managers would regularly address the daily morning assembly, warning that Nissan was catching up, we’ve got to penetrate the American market, GM is powerful, don’t let us end up like Mitsubishi. Toyota used this kind of manipulation to keep wages at average levels and to steadily increase its internal cash reserves.

The result: manufacturing plants in twenty-six countries, total assets of 22 trillion yen ($200 billion), and 2.2 trillion yen ($20 billion) cash-in-hand in the “Toyota Bank.” Annual wage negotiations amount to getting together with the labor union to talk about “the priority of competitiveness,” and the workers and subcontracting companies are left to suffer.

With a thoroughly defanged company union and no countervailing power within the company, Toyota has been afflicted with a series of scandals that are astounding for the home company of the chairman of the Business Federation. The Labor Standards Bureau ordered Toyota to desist from unpaid overtime, the Nagoya tax office discovered 5 billion yen ($45 million) in underpaid taxes, the company was accused of leaking test questions for the national auto maintenance certification exam–all petty, stopgap mess-ups, unworthy of a world-class corporation. In its mind, Toyota is still a provincial company.

The conversation among my friends turned to an accident one early morning in May, where a 33-year old worker was crushed to death in a metal press, followed by talk of suicides, some from overwork, among elite technicians in the development division and among leaders of the labor union. Over the last decade, they said, they’ve seen a dramatic increase in depression among their coworkers.

Articles about mental health care have begun to appear frequently in the labor union newspaper. One report of a November 27, 2003 labor-management council meeting noted that, “the company sees the high incidence of psychological disease as a grave situation.” The report, printed in bold type, amounted to a declaration of emergency.

At a union meeting the previous month, the leadership was asked what had been done to address what they had termed “an urgent issue that must be dealt with.” They responded that the union had pressed the company to adopt preventive measures, early detection, and follow-up of workers on psychological leave, but “this has not led to significant progress.” The union’s demands for last spring’s contract negotiations toadied to the company: “The deterioration of mental health is not a problem that ends with the individual, but can lead to a reduction in the ‘personal drive’ that is the source of the company’s competitiveness and to the loss of precious labor power.”

Since the only goal is to create a workplace environment that “brings about a further increase in Toyota’s competitiveness,” there is little chance that the brake will be applied to the rate of suicide. I spoke with Toguchi Masashi, 67, the son of a Toyota worker who grew up hearing talk of “another fatal accident at the factory today” in the bathhouse of the company housing. He has served seven terms in the city assembly as an anti-Toyota representative. “Living in Toyota City,” he said, “if I am asked what kind of company Toyota is, I say, nobody knows.”

Thirty-one years ago, Toguchi described it as “the city of sorrow.” A succession of mayors has come from Toyota, and nine out forty members of the city assembly were elected from Toyota plants. Auto-related plants account for some 83.7 percent of the city’s factory workers and 95.5 percent of its manufacturing output.

Given this, I visited the head of the city tax office and asked him what percentage of local taxes were paid by Toyota. I was told he’d never thought to calculate that figure. One can only conclude that he can’t say anything without the permission of the lord of the castle. Thirty-one years ago, Toyota accounted for 81 percent of corporate taxes paid in the city. In 1997, it was 68 percent. And now it’s a secret.

Perhaps it’s become the “city of secrets.”

Kamata Satoshi, one of Japan’s leading investigative journalists, worked as a seasonal laborer at Toyota in the early 1970s and wrote a best-selling book about his experiences. An English translation of this book was published in 1982 as Japan in the Passing Lane. His report of a return visit to Toyota’s headquarters appeared in Shukan Kinyobi, July 2, 2004.

Translation for Japan Focus by John Junkerman. John Junkerman is a writer and filmmaker working in Tokyo. His most recent film is “Power and Terror: Noam Chomsky In Our Times”. For another article by Kamata see Government-Business Collusion and Land Giveaways in Central Tokyo.